What is commercial refrigerators and freezer?

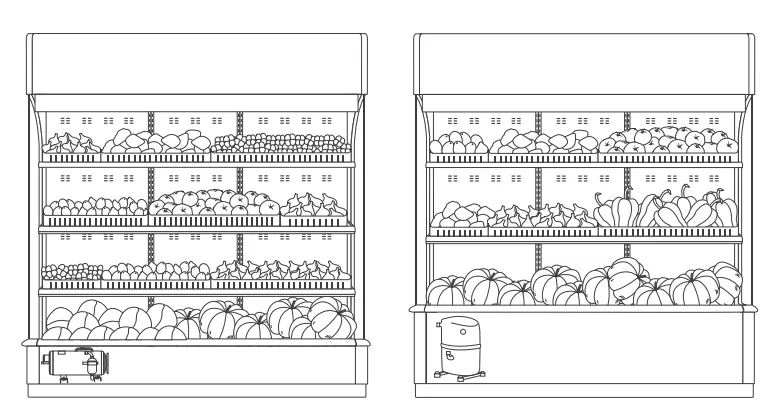

As a terminal equipment in the catering industry, commercial refrigerators serve dual functions of food storage and display of finished products. In today's rapidly developing catering industry, it plays a crucial role. Commercial refrigerators refer to refrigerated or frozen refrigerators used in commercial premises such as supermarkets, beverage shops, freezers, hotels and restaurants to store ice cream, beverages, dairy products, frozen foods, food materials, etc.

Classification of products

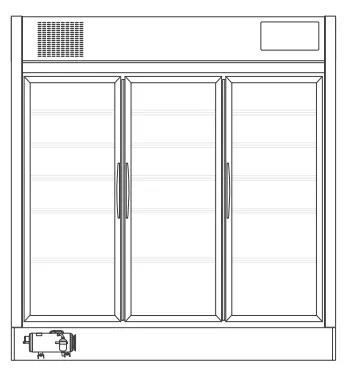

commercial refrigerators (also known as beverage cabinets) and commercial freezer (also known as food freezers)

The temperature inside commercial refrigerated cabinets ranges from 0 to 10 ℃s and is widely used for the storage and sales of various beverages, dairy products, fruits, flowers, etc.

According to the door opening method, it can be divided into vertical (front opening), top opening, and wind curtain type.

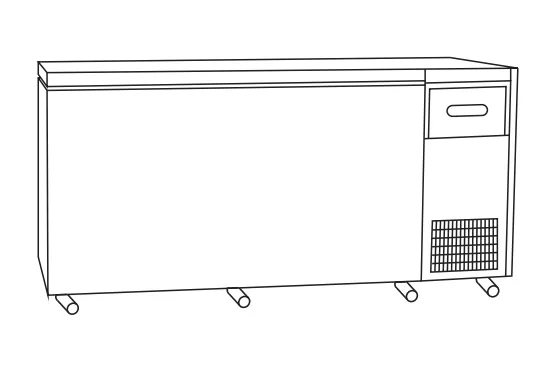

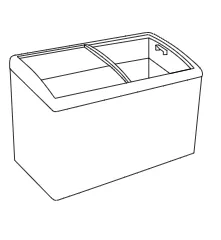

The temperature in the commercial freezer is generally below -15 ℃, which is mainly used for the storage and sales of ice cream, quick-frozen dumplings, rice dumpling, and frozen meat.

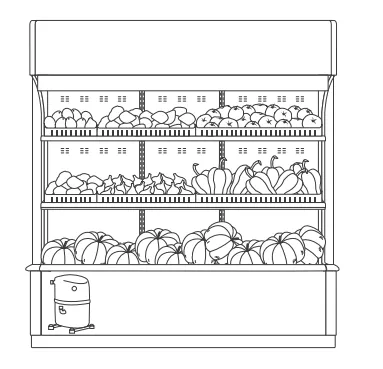

According to structural form and industry usage habits, it is divided into horizontal ice cream cabinets and island frozen food cabinets. Horizontal ice cream cabinets are the mainstream of commercial refrigerators in the market, with common capacities ranging from 100L to 600L; Island style frozen food cabinet, abbreviated as island cabinet, is a popular product type among frozen food customers, seafood operators, and others.

Terminal products used in specific scenarios

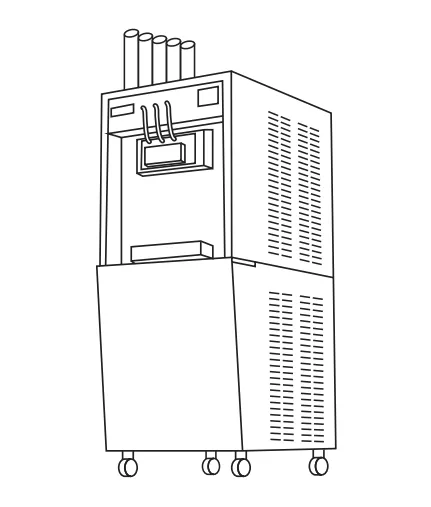

Ice cream machine

An ice cream machine is an integrated device that cools through an internal air or water cooling system. These machines produce soft and refreshing ice cream that can be sold on the streets, in cafes, restaurants, and convenience stores. They are summer dessert machines, usually used in narrow high-temperature environments, so the working conditions of their internal components are very demanding. Manufacturers are required to provide a range of durable compact machinery, electronic controllers, and compressors to meet the many demanding demands of ice cream production processes.

Performance requirements

The core of commercial refrigerators and freezer lies in the refrigeration efficiency of the compressor and the stability of its operation at low temperatures. Whether for commercial or household use, we need to store it and keep it fresh. This principle will not change.

R Refrigeration efficiency: refers to the cooling rate.

1.Refrigerant type : Different refrigerants have different heat transfer performance and pressure characteristics

2.Refrigerant filling amount : The refrigerant filling amount of refrigeration equipment should be reasonable. Excessive charging can lead to insufficient evaporation of refrigerant, thereby reducing the efficiency of refrigeration equipment; However, insufficient charging can lead to insufficient heat absorption by the refrigerant, which can also affect the efficiency of refrigeration equipment.

3.Compressor performance : A high-performance compressor can compress low-temperature and low-pressure refrigerant into high-temperature and high-pressure gas in a short period of time, thereby improving the working efficiency of refrigeration equipment.

4.Environmental temperature : Environmental temperature also has a certain impact on the efficiency of refrigeration equipment. When the ambient temperature is high, the heat dissipation capacity of the refrigeration equipment will weaken, leading to a decrease in refrigeration efficiency; When the ambient temperature is low, the heat dissipation capacity of the refrigeration equipment will be enhanced, thereby improving the efficiency of the refrigeration equipment.

R Stability at low temperatures : Unstable temperatures can cause food to thaw and freeze, making it prone to odors and even spoilage. So stability at low temperatures is particularly important. This will be determined by the compressor and refrigeration pipeline system of the cold chain.

Components of refrigeration products

- Compressor: Rotor compressor can be used, less parts, less wearing parts, high reliability, stable and safe operation, small vibration.

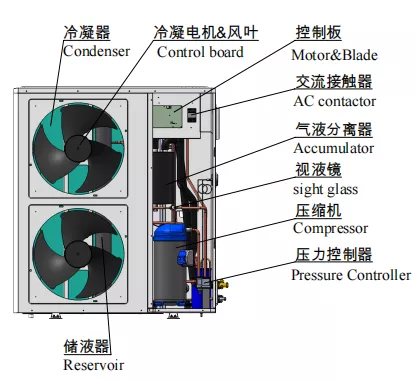

- Condensing unit: Built in plug and play indoor open condensing unit, with high energy efficiency, stable performance, low working noise, and ensuring food safety. Easy to install, maintain, and maintain, using refrigerants with lower global warming potential.

- Controllers, sensors, and valves: This is a rich product line specifically developed for monitoring and optimizing equipment operation and temperature.

- System protectors: such as drying filters, check valves, ball valves, to ensure the normal operation of the system.

Evaluations before choosing a refrigeration equipment

1.What do I need to store when I buy refrigeration equipment?

√ Roots, vegetables, mushrooms, and nuts require 0 ℃ preservation

√ Tea yogurt at around 0-5 ℃

√ Fruits and legumes are stored at around 8-15 ℃

√ Seafood, meat preservation is around 1-5 ℃, frozen below -18 ℃

√ The freezing of ice cream should be below 18 ℃

- Where is the placement?

The position of non display type refrigerated cabinets is relatively fixed

√ Keep a distance from the heat source to prevent it from continuously dissipating heat and working

√ Place in a dry place to avoid moisture in the pipeline

√ Place the compressor on a level ground to maintain its level during operation

√ Do not be too close to the wall, otherwise it will affect the heat dissipation function, at least 20cm or more

The placement of display type refrigerators is similar in principle to non display types. But at the same time, it must meet the following requirements:

√ The location directly opposite the door that customers can see upon entering, which is more prominent

√ A fixed route, a necessary path for customers.

- Is transportation and movement convenient?

Most commercial cold chain products on the market have four universal wheels at the bottom, so movement is not a problem. Even if two of the four wheels fail, the two universal wheels are still enough to move.

- What size should I buy? Measure the length, width, height, and volume of the cooling cabinet body

At present, there are both horizontal and vertical freezer display cabinets available on the market, ranging from 300 liters to 1800 liters, based on actual needs.

Precautions for using refrigeration equipment

- Independent dedicated sockets must be used and reliably grounded. The power cord of the refrigerator is equipped with a (grounded) plug that meets the standard three wire (grounded) socket. Under no circumstances should the third pin (ground) of the power cord be cut off or removed.

- Flammable and explosive dangerous goods, as well as highly corrosive acids, etc., are strictly prohibited from being placed inside the refrigerator

- Once the power supply of the refrigerator is cut off, it needs to wait for more than five minutes before reconnecting to avoid damage to the compressor or system. For maintenance, the power plug must be unplugged. After the refrigerator is installed in place, the plug should be accessible to prevent the power plug from being unplugged in case of danger.

- Do not immediately put food into the refrigerator that has just been powered on. After running the empty cabinet for a period of time (about 3 hours in summer and about 2 hours in winter), put the frozen food into the cabinet for storage.

- After moving the refrigerator, it should be left to stand for at least ten minutes before turning on the power.

- Regularly clean the refrigerator and unplug the power plug before cleaning for safety. Regular dust removal of the heat ex-changer in the cabin can improve heat exchange efficiency and reduce energy consumption.

Compressor——The Core of Refrigerator and Freezer

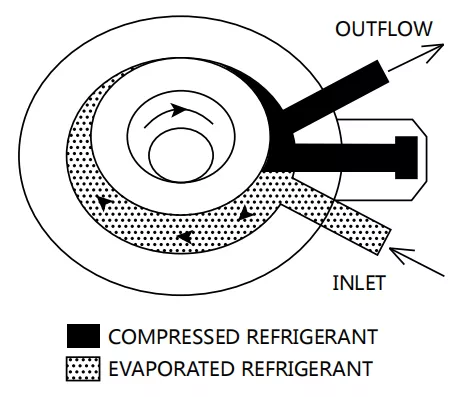

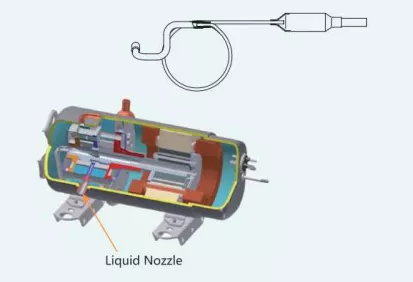

The liquid refrigerant is compressed into a high-temperature and high-pressure gaseous refrigerant using a compressor, and then sent to the condenser for heat dissipation to become a low-temperature and high-pressure liquid refrigerant, so the condenser blows out hot air. Then go to the throttling device (usually using a capillary tube) to throttle and reduce pressure, and enter the evaporator. Due to the sudden increase in space and decrease in pressure after the refrigerant reaches the evaporator from the capillary tube, the liquid refrigerant will vaporize and become a gaseous low-temperature refrigerant, absorbing a large amount of heat. The evaporator will become cold, and direct cooling or air cooling will be used to achieve cooling inside the cabinet.

Advantages of rotary compressors

1.High Efficiency: Rotary compressors are known for their high energy efficiency, particularly in medium to large cooling capacities. They can deliver a high coefficient of performance (COP), resulting in better energy utilization and lower operating costs.

2.Compact Design: Rotary compressors have a more compact design compared to other types of compressors like reciprocating or scroll compressors of similar capacity. This makes them suitable for installations with space constraints, allowing for more flexible system design and layout. Besides, Boyang's horizontal compressors occupy less height than vertical compressors

3.Smooth Operation: The piston machine is in reciprocating motion, while the rotor machine is in circular motion;These compressors operate with minimal vibration and noise levels. The balanced rotary motion of the pistons ensures smooth operation, providing a quieter working environment, which is essential in commercial settings like supermarkets or restaurants.

4.Reduced Maintenance: Rotary piston compressors have a simple construction with fewer moving parts, which translates to lower maintenance requirements. The ease of maintenance helps minimize downtime and servicing costs, improving the overall efficiency of the refrigeration system.

4.Liquid Injecting Technique :Liquid refrigerant from system high pressure side being piped into the compression chamber, cool down the key components and oil, prevent compressor from overheating in high compression ratio working status.

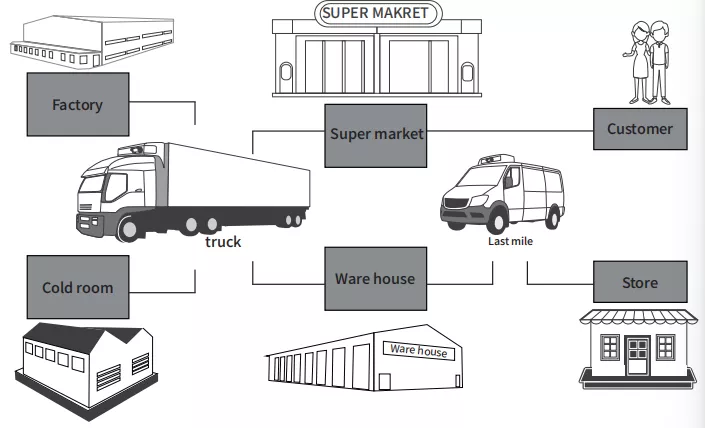

6.Wide range of applications:refrigeration solutions for the whole process from transportation to market.

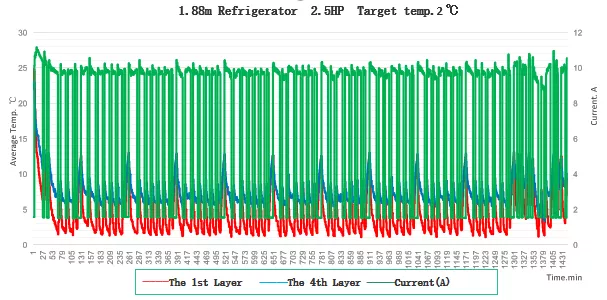

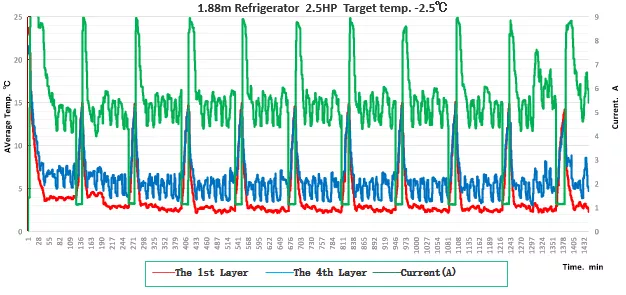

Comparison of fixed frequency and variable frequency units

The biggest difference between fixed frequency and variable frequency is the speed of the compressor, which determines the temperature of the freezer. The speed of the fixed frequency compressor is fixed, while the speed of the variable frequency freezer compressor changes according to temperature. It can be said that the variable frequency freezer is more intelligent, and it can make certain adjustments according to the current temperature situation, which can better keep the temperature constant.

Advantages of variable frequency compressors:

- Better preservation effect: The internal temperature of the variable frequency freezer can achieve a constant change, so the food preservation effect is better. However, the internal temperature of the fixed frequency refrigerator fluctuates, and the temperature changes will reflect on the food, resulting in average preservation effect. It can be said that excellent preservation effect is one of the main selling points of the variable frequency freezer.

- Less noise: Compared to fixed frequency compressors, variable frequency compressors have lower noise and are quieter during operation. Because the fixed frequency compressor starts frequently due to temperature changes during operation, the noise is noticeable. But this situation does not occur with variable frequency compressors. The speed of the compressor can be precisely controlled, and the startup will not be so frequent, so it will be more silent.

- More energy-efficient: The starting frequency of a fixed frequency compressor is much higher than that of a variable frequency compressor. Every time the compressor starts, it consumes a lot of electricity. However, variable frequency compressors are more intelligent and have more precise temperature control, so the compressor does not start frequently, which makes it more energy-efficient. Generally, it can save 10% to 35% energy, and the amount of energy saved depends on the working conditions of the compressor and the setting of the frequency converter parameters.

The data used 2.5HP fixed frequency unit

The data used 2.5HP variable frequency unit

Power input type of compressor

220V 50Hz

115V 60Hz

220V 60Hz

380V 60Hz

Boyard medium and low temperature compressors

Started in 2005, after thorough market validation, with a large market share in China, participated in drafting the Chinese industry standard "Rotary Compressor with liquid refrigerant injection for refrigeration appliance ". Low temperature compressor products are mainly used in commercial refrigeration units and related refrigeration equipment, such as chillers, refrigeration cabinets, small cold storage, supermarket island cabinets, and other medium and low temperature commercial fields.

We hope nature can become a resource that everyone can enjoy and explore - Sustainable Development.

According to a new proposal from the US Environmental Protection Agency, starting from 2025, all common HFC refrigerants with higher GWP will be prohibited from being used in most refrigeration and air conditioning applications. Boyang compressors are compatible with environmentally friendly refrigerants R290 and R404A to accommodate R448 and R449.

Why choose Boyard?

√Mature technology and R&D team to support customer customization needs.

√First-class customer service before, during, and after sales.

√Excellent cooling and diverse exclusive AC design products.

√Good cooperative relationships with domestic and foreign customers, exported to Europe, North America, the Middle East, Southeast Asia.