Rotary compressors can be divided into vertical and horizontal in terms of cylinder arrangement: the central axis of the cylinder is perpendicular to the ground, which is called vertical, and the central axis of the cylinder is parallel to the ground, which is called horizontal. The horizontal rotary compressor was first developed in Japan in the early 1980s. It was mainly used in the field of small-scale low-temperature refrigeration represented by household refrigerators at first, replacing reciprocating piston compressors. Since the horizontal rotary compressor was put into the refrigerator market in Japan in 1980, it has developed into one of the main models of refrigerator compressors at that time. In addition, the open-type horizontal rotary compressor was also used in the field of car air-conditioning due to its advanced performance and compact structure.

Figure 1---Early horizontal rotary refrigerator compressor

Figure 2- Early open horizontal rotary car air conditioning compressor

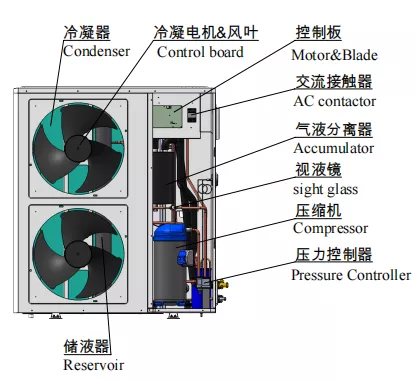

Graphical representation:

1.blade 2. rolling rotor 3.crankshaft 4.frame 5.balance weight 6.motor rotor 7.motor stator 8.balance weight

9.main bearing end plate 10.cylinder 11.secondary bearing end plate 12.frame 13.discharge muffler

14.suction pipe 15.rubber band 16.spring

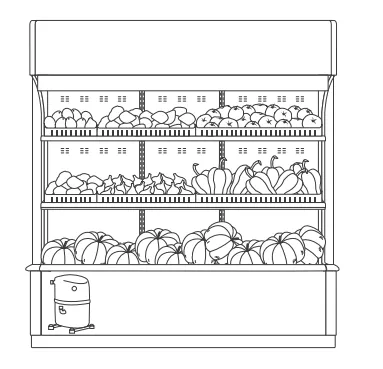

In recent years, with the development of social economy and technology, new application scenarios have emerged. The horizontal rotary compressor has inherited its historical technology application advantages and experience. With its characteristics of short height, low center of gravity, small vibration, and good variable speed performance, it has been further developed and researched and applied in self-contained plug-in refrigeration systems (such as plug-in refrigeration display cabinets, built-in refrigeration display cabinets), roof-mounted RV/railway air-conditioning systems, and new energy electric vehicle air-conditioning.

Horizontal rotary compressors have the following technical features :

- Simple structure, small size and light weight. To gain same cooling capacity, compared with reciprocating piston compressor, the volume of rotary compressor displacement can be reduced by 40% to 50%, and the total compressor weight can also be reduced by 40% to 50% ;

- Fewer components, high reliability, especially less wearing parts, and less friction loss between relatively moving parts, high reliability ;

- Only the bladehas a small reciprocating inertial force, and the rotating inertial force of the double-cylinder compressor can be completely balanced, so the vibration is small and the operation is stable ;

- There is no suction valve, the suction time is long, the clearance volume is small, and the suction is direct, which reduces the harmful overheating of the suction, and the suction efficiency is high ;

- Low processing cost and high volumetric efficiency. The main working contact surfaces of the rotary compressor are circular and flat, with regular and simple shape, which is very convenient for high-precision grinding. The processing and assembly technology is mature and of high-precision, so it has the characteristics of low cost and high efficiency;

- The performance of variable speed is good. The rotary compressor is directly rotated and compressed by the cooperation of the cylindrical cylinder and the rotating rotor. It can directly follow the frequency conversion motor for synchronous variable speed movement without converting the rotary motion into reciprocating motion. Therefore, it has better variable speed performance than reciprocating piston compressors;

- Low height, compact structure, and small size can reduce the installation and layout space of the system and increase the effective volume of the cabinet;

The key technology in the design of horizontal compressors is to solve the reliability of the oil pumping system and exhaust gas flow passage system after the compressor is lying down. Based on this, our company has done a lot of basic research and verification work from the product technology level and application level, and formed a horizontal compressor self-developed technology patent and core technology represented by national standard CN 204458348 U.

Figure 3---Boyard horizontal double-rotor compressor internal structure

Figure 4---Boyard horizontal compressor patent

Through the above technical means, the problem of the oil circuit and air circuit of the horizontal compressor is solved, which can ensure a stable oil level and a good oil pumping effect when the horizontal compressor is working.

In addition, in order to solve the impact of high discharge temperature on the compressor and motor under the high pressure ratio working condition of low-temperature applications of horizontal compressors, we have adopted quasi-secondary compression liquid injection technology in the compressor design technology. By setting appropriate injection holes in the compression chamber of the compressor pump body, an appropriate amount of medium-pressure and low-temperature liquid is introduced from the system into the compression chamber to obtain lower discharge temperature and higher compression flow rate, which improves the performance and reliability of the compressor.

Figure 5---Schematic diagram of the structure of the pump body with injection holes

Figure 6---The circulation diagram of the quasi-secondary compression system

With the diversified high-quality demands of application scenarios in market segments, horizontal rotary compressor products and technologies will continue to make breakthrough in the direction of small and light weight, large capacity, new refrigerant, new structure, low noise, and low vibration.