Water Cooled Condensing Unit

Water Cooled Condensing Unit

Water-cooled condensing unit is a type of refrigeration system that uses water as a medium for removing heat from the refrigerant. In this setup, the condenser coils are cooled by circulating water, which absorbs the heat from the refrigerant and carries it away. The water-cooled condensing unit typically uses a water-cooled condenser, which is a heat ex-changer that facilitates the transfer of heat from the refrigerant to the circulating water.

Advantages of a water-cooled condensing unit

Difference between air cooled condenser and water-cooled condenser

1.Water-cooled condensers use a tube and shell heat ex-changer where plant waster circulates on one side and refrigerant on the other. Air-Cooled use a fined tubed heat ex-changer and motor driven fans or centrifugal blowers to move air through the condenser.

2.The specific heat capacity of water is large, the heat exchange efficiency is high, and the energy efficiency of the whole machine is increased.

3.For R290 systems with limited charge, water-cooled condensers can reduce the system volume and reduce the charge amount of R290

4.Air-cooled units require no facility water hook-up but add heat to the location. Water-cooled units eliminate excess heat, additional airflow, and have a smaller footprint but require a facility water supply.

5.Air-cooled condensers offer simplicity and are suitable for smaller cellars. In contrast, water-cooled condensers provide more efficient cooling and precise temperature control, making them ideal for more enormous cellars or high-temperature environments.

Main parts of water-cooled condensing unit

The compressor : Compression is the first step in the refrigeration cycle, and a compressor is the piece of equipment that increases the pressure of the working gas. Refrigerant enters the compressor as low-pressure, low-temperature gas, and leaves the compressor as a high-pressure, high-temperature gas.

The water-cooled condenser : a heat ex-changer that removes heat from refrigerant vapour and transfers it to the water running through it.

Pressure controller : A device that maintains the normal operation of the refrigeration system when the condensing pressure and evaporation pressure in the system exceed the use of the compressor. Stop the compressor through the pressure protector when the limit is reached.

Gas-liquid separator : the gaseous refrigerant at the outlet of the evaporator may be in a gas-liquid mixed state, and the role of the gas-liquid separator is to put the refrigerant liquid in Gas separation, effectively prevent the compressor liquid strike.

Sight glass : The sight glass can be used to determine whether the refrigerant is properly charged and the water content in the system.

Features of Boyard water-cooled condensing unit

- Include fixed frequency unit and variable frequency unit, horse power from 1 to 12HP;

- Be suitable for MBP&LBP application, Eva, temp. of running range from -40 ~ 5 ℃;

- Charging small volume of refrigerant;

- Able to run with a variety of refrigerant, such as R290, R404A, etc.;

- Able to work together with hermetic dry cooler;

- Simple commissioning, only need to connect with water and wires.

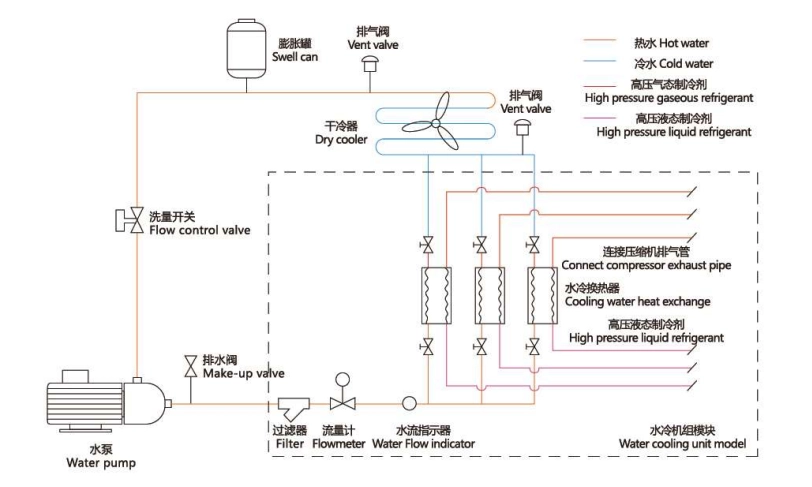

Working principle of Boyard dry-cooler unit

After the refrigerant is compressed by the compressor, the high temperature gas is discharged,and the heat is exchanged by the water-cooled heat ex-changer into the high pressure liquid refrigerant,and the cooling device enters the evaporator for refrigeration.

The high temperature hot water generated by this process is exchanged through the dry cooler and the external environment,and the hot water in the dry cooler and the external environment are exchanged through the fan,and the cooling water enters the water-cooled heat ex-changer and the refrigerant for heat ex-change.

Schematic diagram of dry cooler system